By Dr Joe Mason (Associate Team Leader, Chemistry)

(Image generated using Microsoft Copilot)

What if drug discovery chemists could eliminate the purification steps from their work, without negatively impacting the biological assay data collected?

It’s the simple premise that underpins “Direct-to-Biology” (D2B), a technology that is quickly gaining traction and one with notable publications from “big pharma” that have helped propel the approach into mainstream drug discovery.1–3 In a D2B campaign, compounds are synthesised in plate-based format and the crude reaction mixtures, each containing a single target compound, are screened warts and all in the assay. Assay wells that give the desired activity are resynthesised, purified and retested to confirm the results, whilst those that are inactive are removed from further consideration.

It's an attractive proposal: medicinal chemists know well the laborious nature of purifications, and one only needs to empty the solvent waste once to know how much solvent (with its associated environmental impact) is used in these purifications. Once that pesky purification process is removed, the advantages come quick and fast.

Purchase, or synthesis, of large quantities of starting material? No need – our D2B reactions are performed on the nanomole scale that’s required for the assay rather than what’s needed for a successful purification.

Slow throughput of compounds whilst your assay biology team twiddle their thumbs? No problem – D2B reactions are conducted in 384 well plates, with a correspondingly large library of carefully designed compounds synthesised at a time.

Cost of all those FTEs starting to add up? Not any more – synthesising those compounds in a plate format, each carefully designed to advance our understanding, delivers a cost effective approach to accelerating the drug discovery process.

Of course, there’s a clear and obvious caveat to all this – we’ve been purifying compounds with good reason for decades. Those with a healthy dose of scepticism will point to the multiple case studies that demonstrate the importance of removing impurities like palladium; it’s for this reason that scientists at Boehringer Ingelheim report the use of a Metal Ion Interference Set (MIIS) to assess the impact of common metal ions in the assay,4 and additional scavenging agents are recommended following chromatographic purification.5

This doesn’t mean that Direct-to-Biology is a non-starter though, even for reactions which use transition-metal catalysis. Rather, these informative reports help to signpost the potential pitfalls that come with this approach, so that we can better understand how to proceed. Below are the five key steps for any D2B campaign, starting with compound design and finishing with the resynthesis of hit compounds.

Choosing the Right Hypothesis

A common misconception is that Direct-to-Biology, or library synthesis in general, is about making large numbers of compounds for their own sake or because it’s easy to do so. At Domainex, good science starts with a well-thought-out hypothesis. This hypothesis leads to compound design, for which we must then choose the right synthetic platform to give the highest chance of making the target compounds.

Direct-to-Biology is one pragmatic conclusion to this line of enquiry: oftentimes (but not always) hypotheses can only be answered well by making a large number of compounds. Take expansion at a growth vector for example – at the outset there might be a limited amount of information on what’s tolerated. Do we need polar or greasy groups? Cyclic or acyclic motifs? Large or small? As scientists, we recognise that a single exemplar for each isn’t going to answer our hypothesis – we need a much larger dataset. Even artificial intelligence (AI), the much-touted revolution in drug discovery, needs large datasets to build understanding of what’s required to reach that drug candidate.6

With generative AI and millions of commercially available building blocks available at the click of a button, a library design can feasibly begin with 106 compounds. The very best Direct-to-Biology campaigns are those which make full use of computational tools, docking models and machine learning to whittle down this set to a more manageable size for synthesis. Direct-to-Biology then becomes the final filter before investing precious time and energy into purifying compounds – only compounds which have demonstrated the very best activity in the D2B assay cascade are resynthesised and purified to confirm the assay data.

Choosing the right conditions

Already we’ve discussed the pitfalls of sending crude reaction samples to the assay, which might be summarised in the question “what is the impact of these impurities?”. If a common impurity interferes with the binding of a compound, we’ll get a plate of false negatives; if an impurity binds to the protein itself or interferes with the mechanism of the assay, we’ll get a plate of false positives. What we need is a better understanding of how a reaction mixture containing by-products, side-products, reagents and solvents interact with the assay. Ideally, we’d like to capture the full reaction “fingerprint” – not just the by-products that are well characterised, but also those which might never have been reported.

To examine the potential impact of the crude nature of the samples, we have established a standardised workflow that we refer to as our “D2B compatibility test”. Project-agnostic crude reactions are tested in the assay, both with and without a spiked positive control. These are samples which have been reacted to completion, using reactants that bear no structural similarity to the targeted compounds. They’ll contain a similar fingerprint to that of the D2B reactions but aren’t expected to cause a measurable change in the readout of the assay on their own. When a positive control is added to these crude reactions, the readout should mimic the result seen for the pure positive control, assuming there is no interference.

These D2B compatibility tests enable greater understanding of the effect of the “crude nature” of the samples we plan to test before investing significant time and money in the D2B synthesis step. Of course, if significant interference is observed in the compatibility test and there is no concentration window in which reliable assay data might be obtained, then D2B work should be halted and an alternative method of synthesis explored.

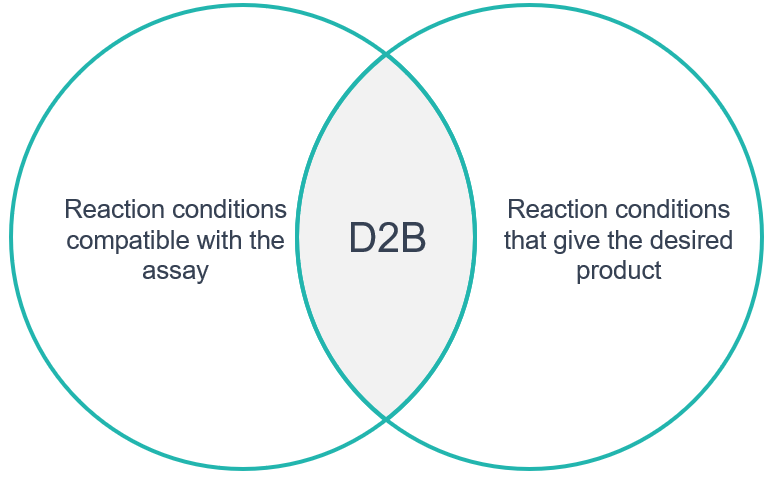

In parallel with this workflow, we optimise the reaction in another plate, 24+ reaction conditions at a time, to find a global optimum solution for the library of target compounds. At the Venn diagram intersection of the conditions that are compatible with the assay and the conditions that successfully make the desired compounds, are the conditions we’ll use for D2B synthesis.

D2B Synthesis

The real power of D2B comes when it’s carried out in a plate format, ideally with access to multi-channel liquid handling capabilities. Automated liquid handlers like the Echo (Beckmann Coulter) or Mosquito (SPT Labtech) can further accelerate the speed of dispensing and enable the scientist to pursue other tasks. An important consideration to take into account is the order of addition of reagents and how to achieve effective mass transfer. Plates with 384 or 1536 wells are simply too small for a stirrer bar, so we must rely on diffusion in reaction solutions. This physical limitation removes solid bases like Cs2CO3 from consideration, but can also come with unexpected consequences. Stevens et al reported their observations for the synthesis of targeted protein degraders (TPD) via an amide coupling between a carboxylic acid and either the HCl or TFA salt of an amine.7 When relying solely on diffusion to achieve homogeneity after dosing, the result was poor conversion that needed “rescuing” through addition of more amide coupling reagent. The authors concluded that there was a lack of diffusion between the “layers” of starting material, presumably leading to decomposition of the amide coupling reagent before the free-base of the amine was released via reaction of the corresponding salt with the base that was added. In contrast, when a mixing step was added by aspirating and dispensing the reaction mixture, full conversion was achieved reliably using both the TFA and HCl salt of this amine with a set of five different carboxylic acid partners.

It’s published examples like this that remind chemists of the fact that engineering challenges, as well as chemical ones, must be navigated during D2B synthesis. Certainly, gaining experience in the field, and ideally the specific transformation, are advantageous when planning a large D2B library.

Reaction Analysis

At Domainex, analysis of the reactions is conducted using a streamlined UPLC-MS method that takes between 1 and 3 minutes per sample to run. This method is optimised to give a balance between reliable separation of analytes and the total run time for the whole plate – even in commercial settings, collection of this data can often be the rate-determining step for hundreds of samples. Coupled with this is the interpretation of the dataset, where partial or complete automation of the process is a must-have. A number of commercial and free software tools are available; we use PyParse,8 an open-source Python script that can produce heatmaps and annotated chromatograms in <4 minutes for a 384-well plate.

The experimentalist must then use these outputs to decide which wells to send to the assay. As UPLC-MS is sensitive only to analytes which contain a chromophore, there are no general hard and fast rules for percentage purity on what is “good enough”. Rather, we take a holistic view and consider the purity alongside the conversion observed, with an understanding of how sensitive the assay is to leftover starting material and impurities.

Hit Resynthesis

Modern D2B platforms also collect EPSA, ChromlogD and microsomal clearance data using the crude D2B samples, in addition to biological activity. The drug discovery team can then use this data to assign a rank order; the very best compounds are resynthesised, purified and tested again in the assay to confirm the results. Thus, the next hypothesis is built on a solid foundation of data originating from purified compounds, whilst still achieving orders-of-magnitude of time and cost savings from filtering the design set using D2B.

Outlook

As new papers and successful case studies continue to be published, the outlook for D2B is bright. The goal, in our opinion, is for the field to demonstrate continued success with metal catalysed transformations, whilst beginning to explore novel platforms like photochemistry, which bring with them access to privileged sp2-sp3 linkages. At Domainex, we recommend that D2B is always considered for use in the discovery of new medicines and we look forward to continuing to work with our clients in this space, for both standalone work packages and alongside complementary approaches.

Stevens, R. et al. Integrated Direct-to-Biology Platform for the Nanoscale Synthesis and Biological Evaluation of PROTACs. J. Med. Chem (2023), 66 (22), 15437 - 15452.

Plesniak, M. P. et al. Rapid PROTAC Discovery Platform: Nanomole-Scale Array Synthesis and Direct Screening of Reaction Mixtures. ACS Med. Chem. Lett. (2023), 14 (12), 1882 - 1890.

Tyagarajan, S. et al. Rapid Affinity and Microsomal Stability Ranking of Crude Mixture Libraries of Histone Deacetylase Inhibitors. ACS Med. Chem. Lett. (2024), 15 (10), 1787 – 1794.

Gerstberger, T. et al. Chasing Red Herrings: Palladium Metal Salt Impurities Feigning KRAS Activity in Biochemical Assays. J. Med. Chem. (2024), 67 (14), 11701 – 11711.

Chatzopoulou, M. et al. Pilot Study to Quantify Palladium Impurities in Lead-like Compounds Following Commonly Used Purification Techniques. ACS Med. Chem. Lett. (2022), 13 (2), 262 - 270.

Brazil, R. How AI is transforming drug discovery. Pharmaceutical Journal (2024), 313 (7987); DOI: 10.1211/PJ.2024.1.322137

Stevens, R., Palmer, H. E. P., Miah, A. H. & Burley, G. A. Factors to Consider for Synthesis in 1536-Well Plates ─ An Amide Coupling Case Study for PROTAC Synthesis. J. Org. Chem. (2025), 90 (6), 2192 – 2200.

Mason, J. et al. Automated LC-MS analysis and data extraction for high-throughput chemistry. Digital Discovery (2023), 2, 1894 – 1899.